Round Two

Our Second Batch of Omni Adjustable Spider Chuck Adapters have arrived! They are all pre sold.

If you guys want on the list for the next batch let me know!

Thanks for the business! These turned out absolutely amazing!

Our Second Batch of Omni Adjustable Spider Chuck Adapters have arrived! They are all pre sold.

If you guys want on the list for the next batch let me know!

Thanks for the business! These turned out absolutely amazing!

A memory of a good old dog Mr. Pooch showed up today. He was the dog I started chasing coyotes with 16 or so years ago.

We managed to kill a pile of them together.

Sure do miss that mutt.

I don’t think I’d hunt half as much if it wasn’t for the dog work.

Hope you all had a blessed evening.

We get asked all the time what our carbon wrapped barrels weight… constantly forget! And as luck would have it I forgot on this one also.

I did remember to weight it when it was assembled. 9 pounds 2 oz with an American Rifle Company Coupe De Grace action, 22 inch 22 Creedmoor Barrel and a manners night hunter stock with the mini chassis.

Thanks for the Business!

God Bless

Three more of our in house Carbon Wrapped 22

Creedmoors. Built on my personal favorite American Rifle Company Coupe De Grace Action are heading out the door today!

Thanks for the business!

We have the best customers

Dear Valued Customers,

•••

FYI, as of October 1st we will be adjusting our barreled action prices to simplify our billing. We are also investing more into on-hand inventory along with shop equipment and skilled talent. This will help to ensure we maintain reasonable lead times while upholding the high standards we’re committed to delivering.

If you are on the fence about purchasing a barreled action, l urge you to submit your order prior to the first of October. This will get you as much savings as possible on your new build.

Thanks for the Business!

We are beyond blessed by you our customers.

God Bless

This is pretty cool to see.

Thank you Blake, Ray and the Manson Precision Reamers team for helping promote our Omni Adjustable Rigid Reamer Holder.

Thanks for the Support and business!

God Bless

https://mansonreamers.com/introduciing-omni-adjustable-rigid-reamer-holder

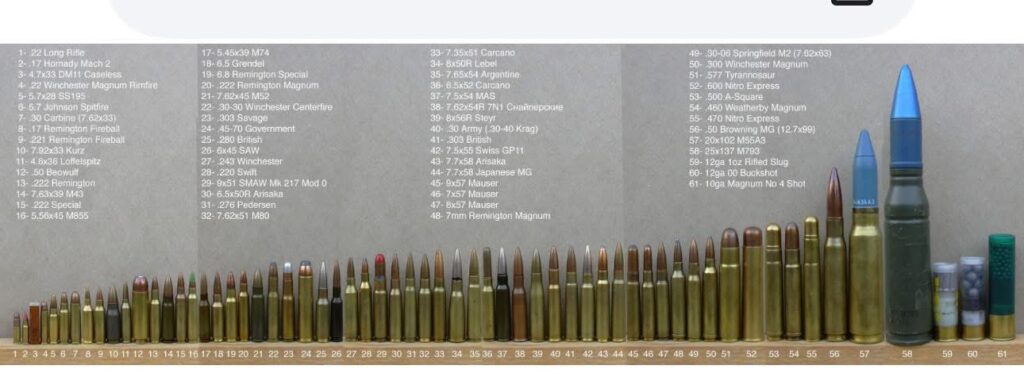

If you spend enough time around hunters or riflemen, one question always comes up:

“If you could only have four centerfire rifle cartridges for the rest of your life, what would they be?”

It’s a strange question for a guy like me-someone who owns 40+ different reamers to support my customers. I get asked for opinions on rifles, calibers, and cartridges almost daily. So why condense all that variety down to just four?

Two reasons:

It’s a fun mental exercise.

Custom rifles are expensive. So are optics, thermals, and all the gear that goes with them.

Personally, I’d rather own four perfectly built custom rifles than 40 factory rifles gathering dust.

Here are my four choices-starting small and working up.

I bet this one surprised some of you. The .204 Ruger is an awesome little round that does a lot more than people give it credit for. It shoots extremely flat, works flawlessly in both AR-15s and bolt guns, has no recoil, and the light bullets tend not to ricochet.

It’s small enough for prairie dogs, yet plenty for raccoons and other tough varmints. In my opinion, it’s one of the most underrated all-around varmint cartridges out there.

No surprise here. The 22 Creedmoor is a coyote hammer at just about any range most shooters can realistically hit them. It has minimal recoil, very little wind dritt, and excellent bullet options with high-quality brass for reloaders.

It’s also legal for night hunting in most states (since it’s still a .22 caliber), which isn’t always the case with the 6mms. And truth be told, inside 300 yards, it’ll do everything a 6mm can do on a deer.

This was the hardest slot to fill. I needed a cartridge that could stretch past 500 yards on deer and antelope, maybe even elk if the conditions were right.

It also needed to be mild enough for long-range practice or late-season coyote calling when they hang up at 500-800 yards.

After looking at ballistics, recoil, and bullet selection, my choice is the 6.5 PRC.

I’ve shot the 6.5 Creedmoor for over a decade with excellent results. The only thing I wished for was just a bit more impact velocity at extended ranges-without moving up to a long action. The 6.5 PRC checks every box, with great brass options (including Lapua) and endless bullet choices.

When it comes to the “big gun” slot, I skipped over the 7mms and 30s and went straight to the .338s. For me the .33 Nosler is the winner.

I’m not a fan of belted magnums, so the .338 Win Mag was out. The .338 Lapua and .338 RUM are excellent but long and less efficient in terms of magazine fit with high-BC bullets. The .33 Nosler offers the power needed for anything-from big bears to long-range elk or moose-without unnecessary compromises.

This is the cartridge I’d want in my hands when I need maximum authority on target.

Final Thoughts

Obviously, this is subjective. Everyone’s list will look a little different depending on what and where they hunt. But as of right now, if I had to narrow down my rifle battery to just four cartridges that cover every situation in the U.S., these would be my choices:

.204 Ruger – varmints and small predators

22 Creedmoor – coyotes, light deer work, night hunting

6.5 PRC – deer, antelope, extended-range general purpose

.33 Nosler – elk, moose, bear, and “anchor it now” hunting

That’s my take.

What about you? If you had to pick just four, what would make your list?

Two 20 inch 1/8 carbon fiber blanks getting sent out to a fellow gunsmith!

Thanks for the business

How heavy is too heavy for you predator hunters?

Personally 15 pounds ready to shoot is my cap.

This includes surpressor, thermal and sling.

I know some guys like feather weight rigs….

But I like a little mass it makes the rifle much more forgiving to shoot in a rush and off a tripod.

Thanks for your input!

American Rifle Company is quickly becoming one of my favorite companies. They aren’t afraid to do things completely different in the industry.

The barreled action in the photo probably looks familiar. It used to be in a Bergara HMR stock – it’s my personal rifle chambered in 22 Creedmoor. I pulled it from the HMR and dropped it into the American Rifle Company Xylo chassis.

First things first when it comes to a stock or chassis for me:

The wood grip is big (which I like!) and cut deep at the back, so the palm of my thumb doesn’t collect unwanted pressure.

AW mags? Absolutely. The only way to run .308/ Creedmoor cases.

Hopefully before long we’ll get the chance to chase some mutts with it.

What are your first thoughts from the photos? Drop them below