Round Two

Our Second Batch of Omni Adjustable Spider Chuck Adapters have arrived! They are all pre sold.

If you guys want on the list for the next batch let me know!

Thanks for the business! These turned out absolutely amazing!

Our Second Batch of Omni Adjustable Spider Chuck Adapters have arrived! They are all pre sold.

If you guys want on the list for the next batch let me know!

Thanks for the business! These turned out absolutely amazing!

This is pretty cool to see.

Thank you Blake, Ray and the Manson Precision Reamers team for helping promote our Omni Adjustable Rigid Reamer Holder.

Thanks for the Support and business!

God Bless

https://mansonreamers.com/introduciing-omni-adjustable-rigid-reamer-holder

Barrel Runout, Reamer Alignment & Why Holder Design Matters

When chambering a rifle barrel, the first step is dialing out both types of runout:

Radial Runout – Bore centerline offset from the spindle axis.

Angular Runout – Bore tilted relative to the spindle axis.

Correcting both ensures the bore is centered and parallel to spindle rotation.

After the Barrel’s True – The Reamer Holder Matters

Most floating holders only compensate radially, not angularly, and can droop during use-causing misalignment, chatter, scratches, or oversized chambers.

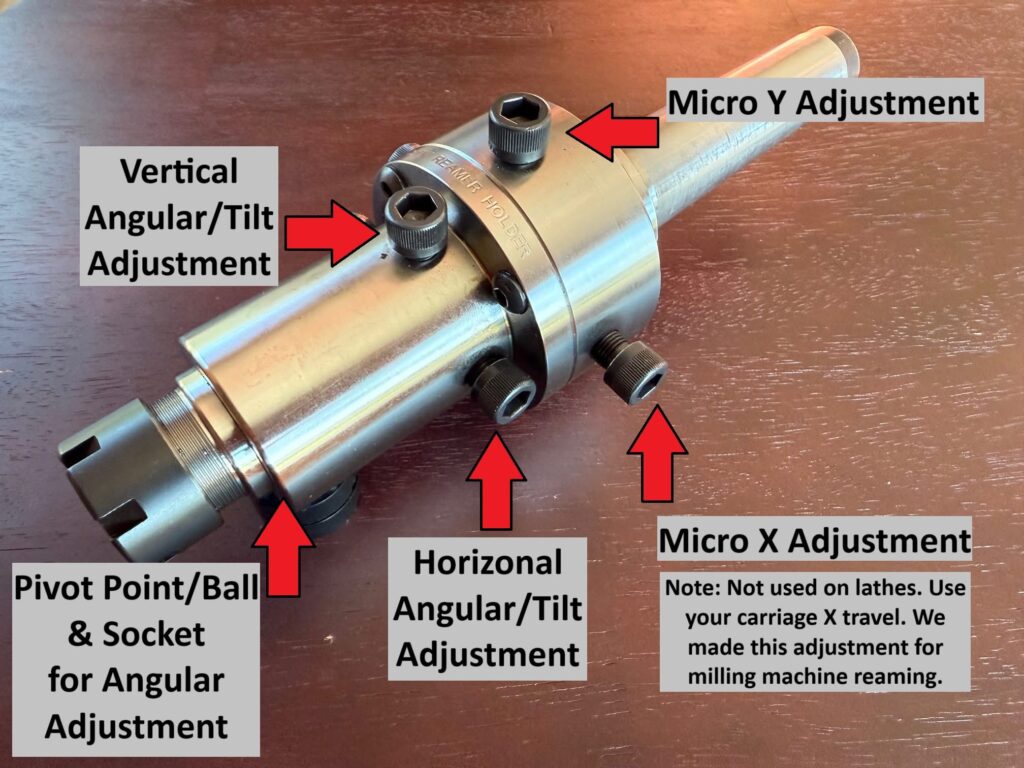

From Drews Precision, the Omni Adjustable Rigid Reamer Holder is not a floppy floating tool. It’s rigid; adjustable both radially in X and Y and angularly in all directions to remove any tilt or misalignment from collets or tool post to adjust the reamer dead true to the spindle.

Advantages:

Rigid stability prevents chatter.

Micro adjustable in all planes to remove angular and radial run out for exact alignment.

No side-load = no oversized chambers.

Rigid means no droop = no scratches or galling.

Repeatable, consistent results.

Bottom line: Eliminate runout in the barrel, align the reamer perfectly, and cut with zero flex.

The Omni Adjustable Rigid Reamer Holder delivers chatter-free, concentric chambers.

The Omni Adjustable Rigid Reamer Holder was designed to be held by the carriage of a lathe, not the tail stock. The carriage is much more accurate than the tail stock. It you try and use this in the tail stock, you will never be able to get it adjusted due to the tail stocks non-repeatability and sag that they are plagued with. If you do try this, you will find out why you should not be using your tail stock to cut chambers.

Included is the indication jig to indicate the reamer to the spindle bore while it’s being held in the Omni Adjustable Rigid Reamer Holder. The two Interapid .0001/10th indicators are not included.

Starting closest to the Omni Adjustable Rigid Reamer Holder collet, make your X and Y adjustments to remove all the runout on the right-hand indicator.

Once this is accomplished, use the angular adjustments to indicate the tip of the reamer, where the pilot is located, to remove all angular runout. Then go back to the right-hand gauge, make your X and Y adjustments as it could have changed with the angular adjustments.

Note: The first time you set this up, it will take multiple adjustments to get the reamer holder true to your spindle. Subsequent set-ups will only require fine adjustments after the initial setup.

Thank you for choosing Drews Precision’s Omni Adjustable Rigid Reamer Holder.

It you’re tighting rigidity problems, chatter, or tire of wasting time indicating barrels for chambering or muzzle work – this is your solution!

Say goodbye to:

-chamber runout and setup

-movement during machining.

-Independently adjusts radial and angular runout

-get dialed in fast and dead-on.

Fits both 6-inch and 8-inch face-mounted chucks.

Spider bolts have ball-and-socket aluminum pads that conform to your barrel no need to make sleeves!

Works great for truing actions and bolts too when paired with a 4-jaw chuck and aluminum soft jaws.

Check out our YouTube page on how we chamber and indicate every barrel using this adaptor!

If you’ve ever wanted a full start to finish look at how our builds are completed; now’s your chance to see the magic happen! Dustin has been hard at work filming a step by step video showcasing our most recent 33 Nosler build. Visit us on our Facebook or YouTube channel to see the latest look behind the curtain and ask any questions you may have.

As always, we enjoy hearing from you and thank you for your business!

We are excited to give you a sneak peek of our Omni Adjustable Spider Chuck Adapter, designed to revolutionize your rifle barrel chambering and threading process!

If you’ve been struggling with:

Our Omni Adjustable Spider Chuck Adapter is your solution! Engineered to ensure precision and stability, this adapter simplifies complex barrel work, reducing errors and ensuring a smoother, more efficient operation. No more sacrificing accuracy or rigidity!

Stay tuned for the official release video!